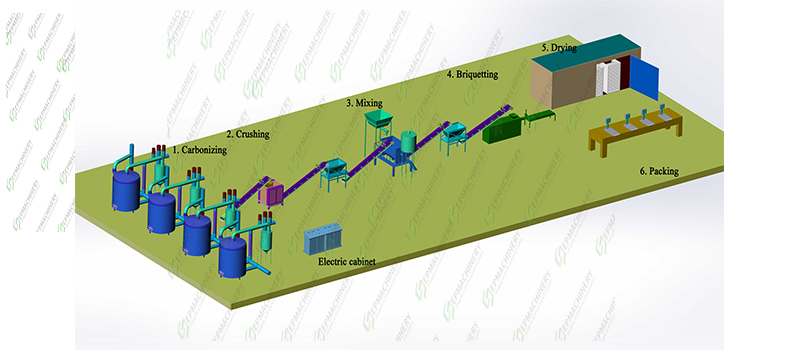

Charcoal barbecue carbon production line process

Charcoal BBQ production line

Carbonization

1. Carbonization treatment: Load biomass raw materials such as wood, straw, and rice husks into the carbonization furnace, carbonize them under high temperature and oxygen-free conditions, and convert them into charcoal blocks or charcoal powder.2. Carbonization equipment: lifting carbonization furnace

The lifting carbonization furnace is a device that realizes layered carbonization of raw materials through a vertical lifting design. Its core feature is the combination of gravity and high-temperature pyrolysis to optimize carbonization efficiency and thermal energy utilization.

Crushing

Crushing of carbonization products: Carbonized charcoal blocks need to be processed into charcoal powder by a crusher, and the particle size is controlled at 1-5mm to adapt to subsequent extrusion molding.Double-roll crusher: The double-roll crusher crushes the material through two parallel and counter-rotating cylindrical rollers. The material enters the gap between the two rollers from the feed port and is crushed under the extrusion and grinding action of the rollers. The crushed material that meets the particle size requirements is discharged from the bottom, and the material that does not meet the particle size requirements is rebounded and continued to be crushed.

Mixed binder

Mixed carbon mud: Mix the carbon powder with the binder (such as starch, bentonite, etc.) in proportion, and control the moisture content at 12%-15% to improve the molding strength.Mixing equipment: spiral ribbon mixer, encryption machine or wheel mill mixer

Three kinds of mixing equipment can be selected

Rod extrusion

Rod making machine working principle: Use a high-pressure screw propeller (wear-resistant alloy material) to squeeze the carbon mud through the mold to form a rod-shaped solid fuel (usually 3-8cm in diameter).

Charcoal powder extruder machine