From material to pellet products

- 2019-12-13 10:18:00

- E.P Original

- 1130

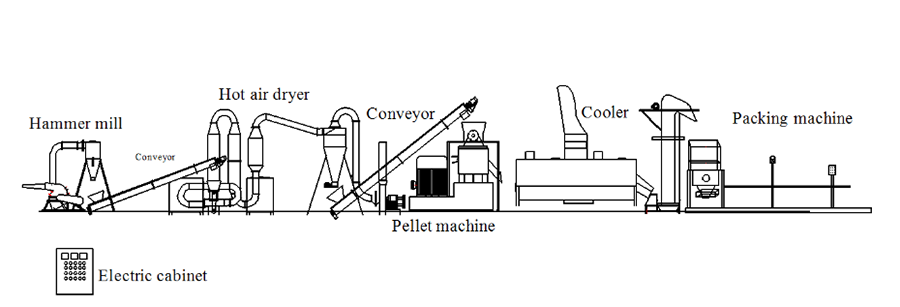

There are several procedures to make pellet products from some biomass materials. In the following content, I will list the detailed procedures in order.

Crushing process:

This is the first step to make pellet products. At this step, raw material should be crushed into small particles. For this process, there are many different crushing machines for you to choose. For processing different materials, you should use different crusher machines. For example, it is better to use a hammer crusher to process wood lumps.

Drying process:

It is not a necessary process. Some material is too wet and can not be pelletized directly. Therefore, before the pelleting process, the crushed material need to be dried to some degree. The suitable moisture content of the material should be among 15-20%. If your material is dry enough, then the drying process could be passed.

Pelleting process:

Pelletizingprocess is the most important part of the whole production line for making pellets. In this process, the powdery material will be formed into even pellet products. Pellet making machines play an very important role here.

Cooling process:

Like drying process that I have mentioned above, cooling process is not necessary, either. The just-finished pellets are warm products. If the capacity of the pellet making machine is not large, you can let the pellet products cool down naturally. However, for large-capacity pellet making machines, we suggest you equip a cooling machine for the production line.

Screening process:

During the production, some wood pellets that can not reach the standard. For example, some pellets are too short. To separate the finished and unfinished pellets, a screening machine will be used. The unfinished pellet products will be separated out. Then, through a conveyor, those unfinished pellets will be put into the feeding port of the wood pellet machine and be pelletized again. Therefore, the raw materials can be fully utilized.

Packing process:

Packaging process is the last step of whole pellet production line.This work can be done manually or with an efficient automatic packaging machine. You can choose either way according to the actual situation.

E.P Machinery can manufacture all the equipment needed in the pellet production chain. In addition, we will also provide perfect pre-sales and after-sales service.